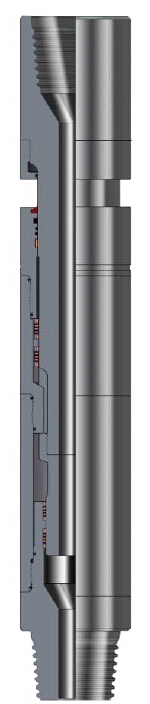

Double-way Shock Absorber SJ

Product Detail

Double-way Shock Absorber SJ

Technical Features

Model “SJ” Two-Way Shock Sub should be mounted on drill string which is near the bit. It can slow or sorbs the longitudinal bounce and peripheral torque impact of drill bit (drill string) simultaneously. It should realize the best fitting of drill pressure and rotation rate as to reduce the drill cost and improve the drilling efficiency. It can be used for the drill-in or coring of hard layer, gravel layer and soft-hard interlayer.

Working principle

The torsion of bottom hole will be changed with changes in bit structure ,formation and bit weight .When the drilling speed reaches up to a certain value ,torque and resonance will be happened to drill string .During rotation drilling , the lower part of drilling tool simultaneously bear axially pressure and torque. When bit weight exceed the limit value, the drilling tool will produce a transverse bending (it means lose steadiness) and torque can also make the drilling tool to lose steadiness to be turned into a twist shape. Two positions are very typical:

1. The lower bit is suddenly frozen and then torque bumping will be produced unless the cut down rotary energy.

2. Reversing operation in force.

The vertically damping unit is made of mandrel, piston assembly, annular space damping unit and liquid spring of working chamber . Working mechanism: To absorb or release the vibration energy of bit and drill string by means of compressible liquid producing spring deformation in working chamber under the function of pressure. The mandrel moves axially relative to outer barrel when liquid spring is in compression or explanation. Meanwhile ,the non-compressible liquid in damping chamber flows through damping space and produces a large number of friction heat so that some vibration and bumping energy are used up . The vertical bumping unit thus can absorb or reduce the drilling tools’ energy in vertical vibration and bumping.

The piston change-over unit is composed of spline outer barrel which is connected with piston by rectangular spline pair and the piston inner hole which is connected with mandrel by ladder-shaped spiral pair. Such a group unit can turn the torque vibration and impact load into vertical component of force in working chamber in a twinkling of an eye so that a constant torque is maintained on.

Technical Parameters

Model

| O.D mm/in | I.D mm/in | Connection API | Max.Working load kN/lbf | Max.Working Torque kN·m/lbf·ft | Max.Drill pressure kN/lbf | Max.Working Stroke mm/in | Rigidity kN/cm | Overall Length Mm/in |

SJ121 | 121 4-3/4 | 38 1-1/2 | NC38 | 1000 224800 | 10 7300 | 300 67000 | 100 3-15/16 | 3.0~5.0 | 4208 165.66 |

SJ165 | 165 6-/2 | 48 1-7/8 | NC46 | 1500 337200 | 15 11000 | 350 78600 | 120 4-3/4 | 3.0~5.0 | 5494 216.29 |

SJ203 | 203 8 | 65 2-1/2 | 6 5/8REG | 2000 449000 | 20 14000 | 450 101000 | 120 4-3/4 | 3.0~5.0 | 6080 239.37 |

SJ254 | 254 10 | 71.4 2-3/4 | 8 5/8REG | 2500 562000 | 25 18000 | 600 134000 | 120 4-3/4 | 3.0~5.0 | 6400 251.96 |

SJ279 | 279 11 | 76.2 3 | 8 5/8REG | 3000 674000 | 30 22000 | 600 134000 | 160 6-1/4 | 3.0~5.0 | 5580 219.68 |

Above list some models, other models also can be supplied as follows:SJ159(6-1/4"),SJ178(7"),SJ229(9").

Add: Room 2-1014,3rd building,Deyi international center,No.6 Changqing 2nd road,

Economic and technological development zone,Xi'an,china

Tel/Fax: 0086-29-89612241 Email: Sales@brj-oiltools.com http://www.brj-oiltools.com