KXJ Fishing Bumper Sub

Product Detail

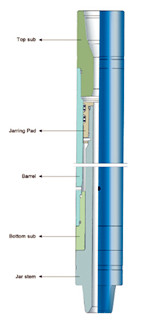

KXJ Fishing Bumper Sub

Technical Features

KXJ type bumper jar (hereinafter called as bumper jar )is a mechanical jarring tool . It can make jar repeatedly the stuck drill stem to free from stuck point. When stuck drill stem can not be released by lifting and jarring, the bumper jar can be rotated to make releasable fishing tool to release fish. When used with mechanical internal cutter, it can provide an expected feeding force to the internal cutter so as to cutting steadily. When used with reversing unit , it can compensate the rising stroke for threads after reversing.

Working mechanism

● Energy conversion in jarring operation

Jarring downward is made by means of energy conversion. Raising drill stem shall make bumper jar to be pull down at a certain height to produce potential energy. Go on raising drill stem, the drill stem has a strain energy due to spring strain. When drill stem is lowered suddenly , the energy stored in drill stem force the drill stem to move downward in acceleration. When bumper jar reach a closed position, the above two energies at this instant change into large downward jarring force.

● Main factors having influence on jarring force

The bigger hanging weight on top drill stem of bumper jar makes a bigger jarring force;

The longer the spring extension of drill stem is when raising drill stem, the bigger the jarring force is;

The longer the stroke of the bumper jar is , the bigger the jarring force of jar is .

Technical parameter

Parameter/Model | KXJ31B | KXJ42B | KXJ44B | KXJ46B | KXJ62B | KXJ70B | KXJ76B | KXJ80B | KXJ85B | KXJ90B |

Product Code | 0401100 | 0405000 | 0406000 | 0408000 | 0410000 | 0413000 | 0414000 | 0415000 | 0419000 | 0416000 |

O.D. (mm) | 79 | 108 | 114 | 121 | 159 | 178 | 197 | 203 | 219 | 229 |

I.D. (mm) | 25.4 | 38 | 38 | 38 | 51 | 70 | 70 | 70 | 76 | 76 |

Sealing pressure (MPa) | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

Max. tensile load (kN) | 300 | 700 | 1120 | 1200 | 1430 | 1530 | 1630 | 1630 | 1630 | 2200 |

Max. work torque (kN.m) | 3 | 6 | 7 | 8 | 13 | 15 | 20 | 20 | 20 | 25 |

Work stroke (mm) | 508 | 1000 | 1000 | 1000 | 1400 | 1400 | 1500 | 1500 | 508 | 1500 |

Connection | 2 3/8 REG | NC31 | NC31 | NC38 | NC50 | NC50 | 6 5/8 REG | 6 5/8 REG | 6 5/8 REG | 7 5/8 REG |

closed length (mm) | 1410 | 2100 | 2100 | 2110 | 2604 | 2650 | 2730 | 2730 | 1769 | 2760 |

Weight(kg) | 45 | 95 | 130 | 146 | 240 | 330 | 430 | 455 | 383 | 660 |

Add: Room 2-1014,3rd building,Deyi international center,No.6 Changqing 2nd road,

Economic and technological development zone,Xi'an,china

Tel/Fax: 0086-29-89612241 Email: Sales@brj-oiltools.com http://www.brj-oiltools.com